Laminarven 66 mm

Terminal or air return filtration in clean rooms and laminar flow cabins.

Terminal or air return filtration in clean rooms and laminar flow cabins.

Type: Laminar Flow HEPA/ULPA Panel.

Frame: Extruded and anodised aluminum profile.

Filtering Element: Glass microfiber paper.

Separators: Thermoplastic glue beads.

Sealant: Polyurethane.

Protective grid: Steel grille on both sides white epoxy painted.

Gasket: Bicomponent polyurethane liquid system. (Continuous semi-circular expanded polyurethane.)

Optimum pressure for filter fixing: 35KPa

MPPS Efficiency: 85%, 99.95% and 99.995%

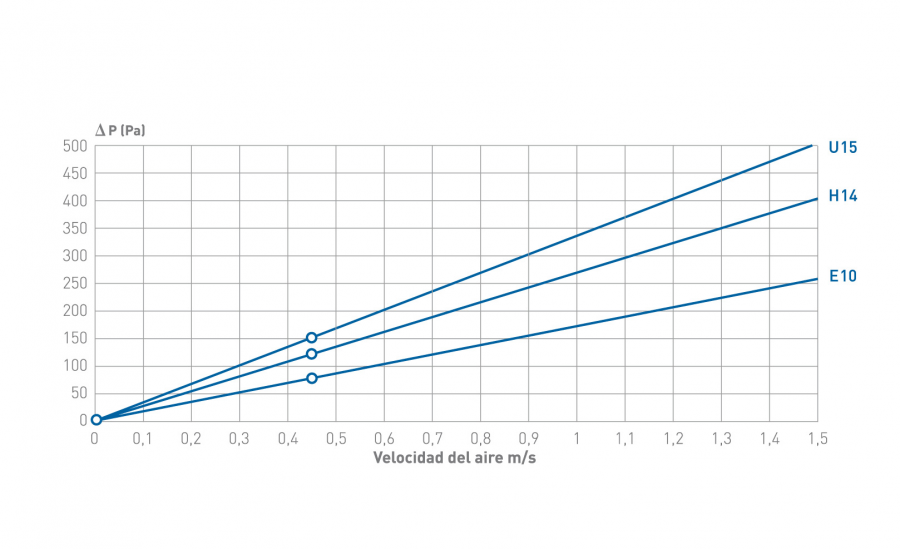

EN 1822 Class: E10, H13 and H14.

Recommended Final Pressure Loss: 600 Pa.

Temperature: 80ºC in continuous service.

– Protective grids on both sides.

– 100% scanned, in accordance with Regulation EN 1822-4.

– DOUBLE LABELLING.

– Strict quality controls verify the degree of filtration and pressure drop.

– All our filters are subjected to an individual scanning test in order to guarantee their optimal perfomance.

– The individual filter test consists of monitoring the nominal flow rates in order to determine the pressure loss and a scan made with a monodisperse aerosol (DESH) in accordance with Regulation EN 1822 (Annexed 4) in order to verify the absence of localized leaks and to determine the actual value of its integral effectiveness with respect to maximum penetration particle size (MPPS).

– Once these tests have been carried out, each filter is given a control label which indicates its serial number, its performance and load loss, with respect to the test flow rate.

– All filters come with an individual test certificate.

– Suitable food industry.

– ATEX version available.

Photo detail seal

*UxP: Units per box *Stock

F: Manufacture, S: Stock, SL: Limited Stock