Laminarven Plus 90/110 mm

Terminal or air return filtration in clean rooms and laminar flow cabins.

Terminal or air return filtration in clean rooms and laminar flow cabins.

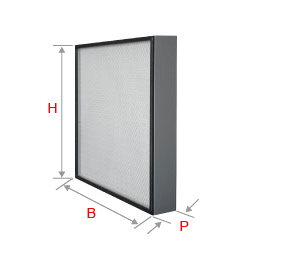

Type: Laminar Flow HEPA Panel.

Frame: Extruded and anodised aluminum profile.

Filtering Element: Glass microfiber paper.

Separators: Thermoplastic glue beads.

Sealant: Polyurethane.

Protective grid: Steel grid on both sides; white epoxy painted.

Gasket: Bicomponent polyurethane liquid system. (Continuous semi-circular expanded polyurethane.)

Optimum pressure for filter fixing: 35KPa

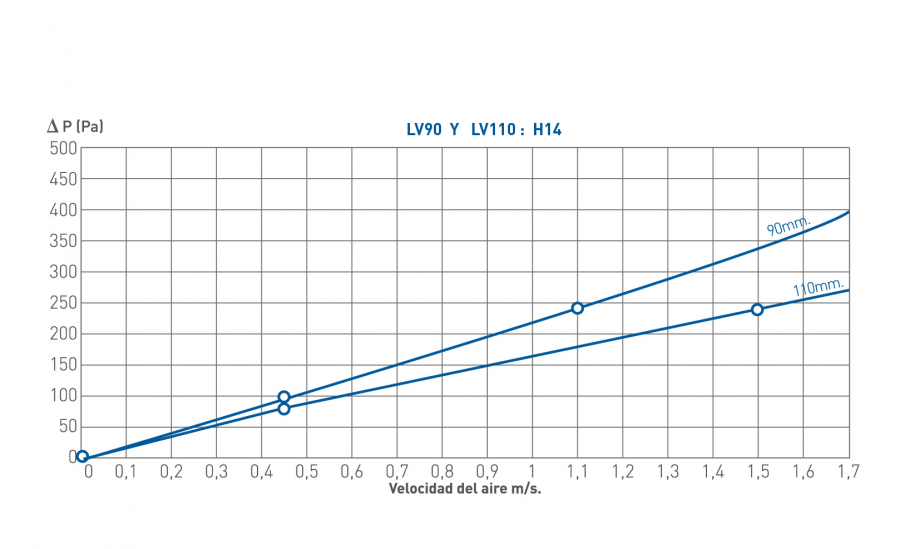

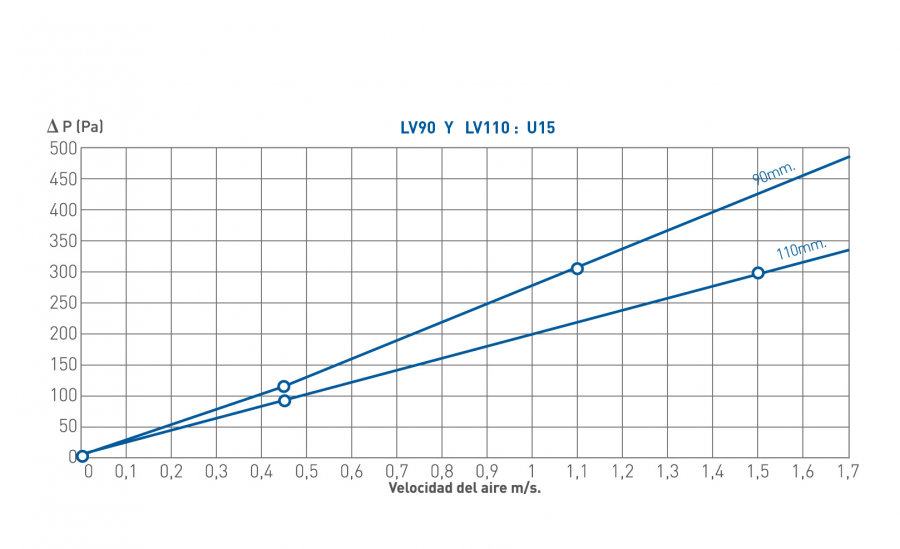

MPPS Efficiency: 85%, 99.95% and 99.995%

EN 1822 Class: E10, H13 and H14.

Recommended Final Pressure Loss: 600 Pa.

Temperature: 80ºC in continuous service.

– The V-shaped pleating method guarantees the optimal fold geometry and a uniform distance between them, resulting in a lower Pressure Drop with higher airflow rate..

– V-shaped pleated technology allows to remove the aluminium separators and therefore eliminating the risk of leaks due to perforations due to the aluminum separators.

– The total use of the filter surface in addition to an even dust deposit thanks to the new pleating technology results in longer equipement lifetime.

– Protective grids on both sides.

– 100% sacnned, in accordance with regulation EN 1822-4.

– DOUBLE LABELLING.

– Suitable food industry.

*UxP: Units per box *Stock

F: Manufacture, S: Stock, SL: Limited Stock